Mesher fault and fix for thin shells and holes

The 3rd party mesher Femdesigner uses (with permission) is 'Netgen', under the LGPL license. It's not easy building a mesher and a free mesher keeps overall costs down. Notice that the license is only asked for when the solver is invoked so meshing is free - albeit of little use without the solver.

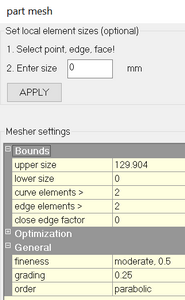

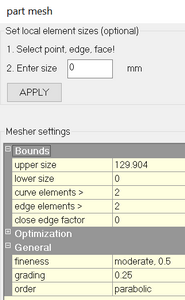

There is one annoying random fault with Netgen that is not highlighted well enough by the help file and that is the tendency to produce elements which traverse the entirety of a hole. To illustrate this I created a simple cylinder of 100mm diameter, 2.5mm thick and 500mm long. The default mesh parameters are shown below.

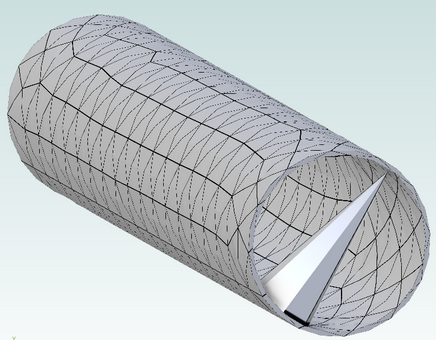

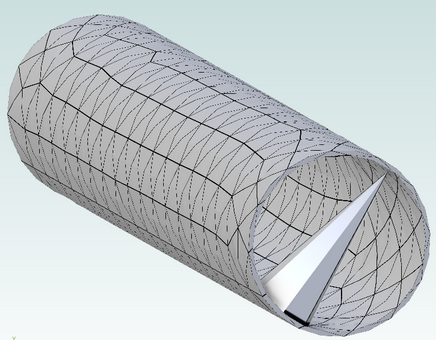

The upper size is a simple guess based on a fraction of the bounding area so it works ok on bulky parts but not very well with thin parts. Keeping the upper size as default gives the mesh shown below.

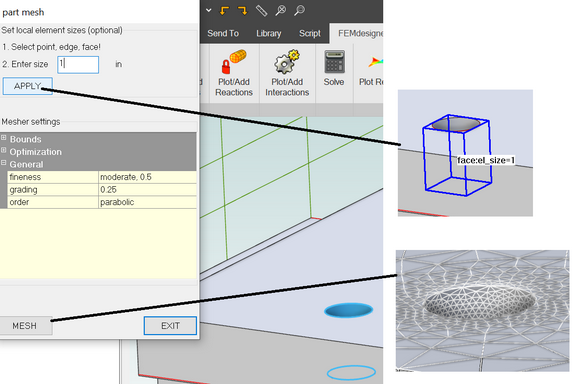

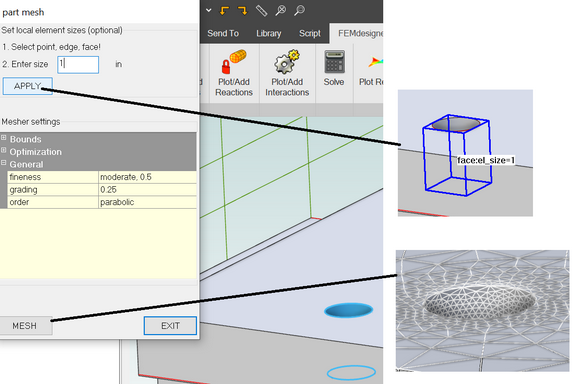

So check your mesh does not have this problem prior to loading it if you have interior holes. This error is fixable by using a more appropriate upper element size, say 10mm which gives an aspect ratio of 10/2.5=4/1 for the elements. Or you can create a local element size as illustrated in the following picture for a small hole (where this problem also sometimes occurs).

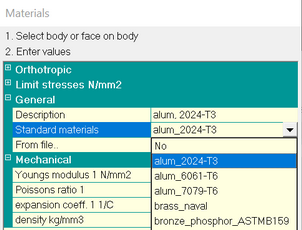

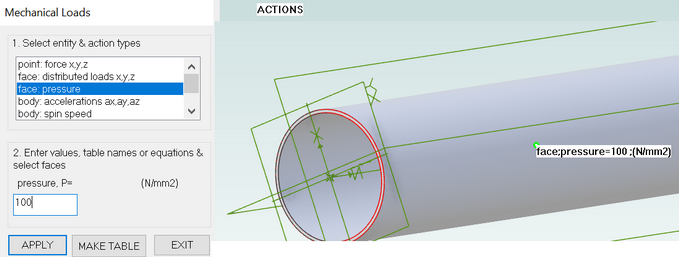

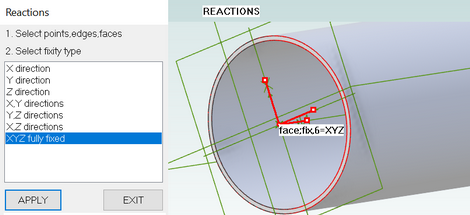

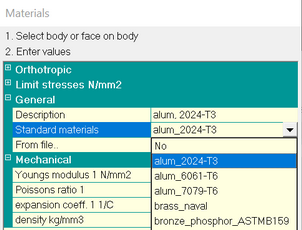

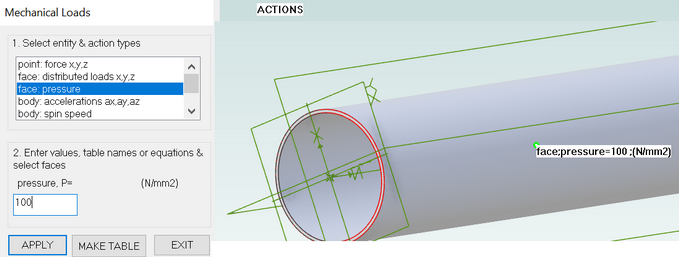

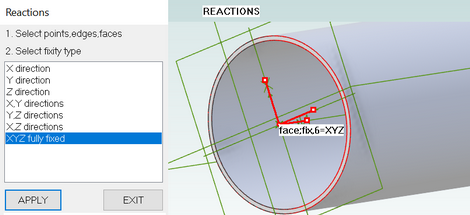

You won't obtain sensible results with such a bad mesh. Continuing with the good mesh, by applying a material, action and reaction as below.

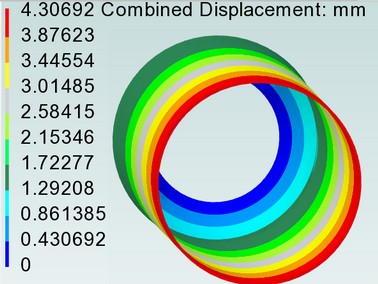

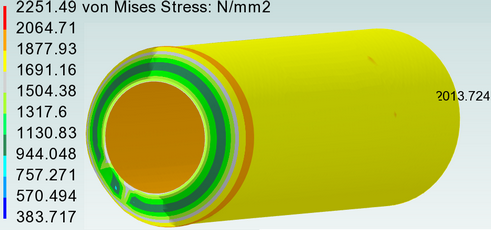

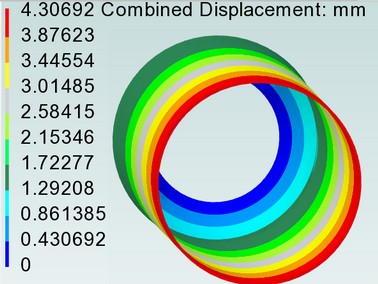

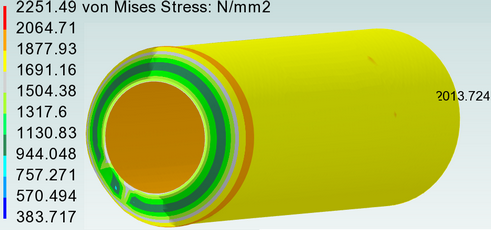

Then solving gives results as shown below.

The stress at the free end is well predicted by the equation pressure x radius/thickness. Notice the pinched end due to the restraint of radial expansion. To remove this effect you need to be smarter about boundary conditions. For example use a quarter model with symmetry reactions/restraints. Or don't worry about it if not in the region of interest. For a cylinder at 2.5(radiusxthickness)^0.5 from the end these end effects will be negligible.

Be sure to check the displaced shape plot (magnification 2 in the plot below). With a slightly higher maximum element size of 15mm the mesh still produces no 'needle-type elements' but the higher elongation (aspect ratio) of the elements gives a resultant displacement plot with an uneven (even ridiculous) expanded shape and the stresses derived from these displacements are therefore inaccurate. So for safety use a maximum of 4/1 aspect ratio for such thin shells.